Mattias HEJDESTEN

CFD engineer - Volvo Car Corporation, Fluid Dynamics Center

Abstract

CFD is today an important tool in the vehicle industry around the world. At Volvo Car Corporation, CFD has become an integral part of the engineering and design optimization process. More and more CFD is used as a tool to help making project decisions and not only serve as support or input to physical testing. The CFD group at Volvo Car Corporation supports project decisions with virtual development in the following areas: aerodynamics, dirt and snow deposition, aeroacustics, thermodynamics and climate systems .

A general overview of CFD at Volvo Car Corporation today will be presented. Tools and methods used for aforementioned applications will be discussed. Special attention will be given to aerodynamics in the vehicle development process. How do we make an impact on the product using CFD? A short description of some of our current and future research topics will also be presented.

Per ELOFSSON

SCANIA CV AB, Fluid Mechanics

Aerodynamicist

Abstract

This lecture will describe the role of experimental fluid dynamics in the design process for automotive vehicles. In addition, the lecture will present an overview of truck aerodynamics and highlight the differences compared with passenger car aerodynamics.

Wind tunnels designed for automotive testing will be presented and the function of the wind tunnel systems that are specific for vehicle aerodynamics will be explained. Traditionally, experimental methods for automotive testing have been aimed at flow visualization and direct force measurements using an external or internal force balance. In today's vehicle testing, balance measurements are often used together with pressure and velocity field measurements. The additional pressure and velocity data are used in wake-analysis methods and the results help to identify which vehicle regions that need to be improved.

Examples from project and research work at Scania will be used to illustrate the topics above.

Dr. Alexander Orellano

Bombardier

Manager, Center of Competence for Aerodynamics & Thermodynamics

Abstract

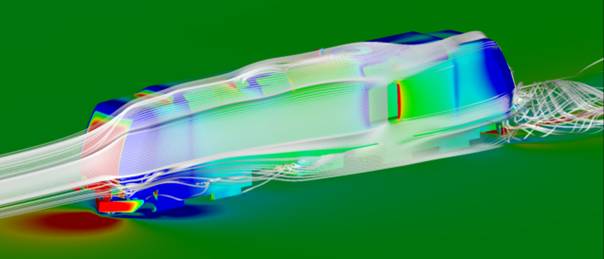

High-speed trains exhibit many complex flow features: reverse-flow regions,

cavities and stagnation points in the gangway and bogie region, laminar-turbulent

transition in the nose region, turbulent boundary layer development, separation

and re-attachment as well as Kàrmàn-vortex streets at the pantographs

contact strip are some examples.

New European legislation is forcing high speed rail manufacturers to reduce the

aerodynamic loads on the surrounding infrastructure, on people waiting at platforms

and on workers at the track. Furthermore, it is the aerodynamic noise which is

the dominant noise source on high-speed trains.

Thus, aerodynamics is nowadays an indispensable topic in the rail industry. This

lecture will address the most critical aerodynamic issues during the development

of a high-speed train including cross-wind stability, head pressure wave generation,

slip stream effect and aeroacoustics. Available methods and their suitability

for the determination of the aerodynamic performance will be discussed, i.e.

analytical equations, Computational Fluid Dynamics (CFD), scaled model testing

in wind tunnels and testing on the train itself.

Dr. Tristan Favre

Renault Sport F1 Team

CFD Engineer